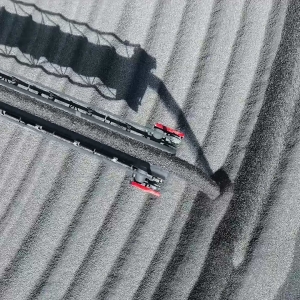

Bucket elevators

These types of equipment are suitable for vertical transport, manufactured mainly for industries and the construction industry. They are completely enclosed, transport dust-free at relatively high transport speeds. They are self-supporting, but must be secured at certain points to prevent horizontal movement.

GBW Models and capacities

Different delivery capacities from 10 to 500 m³/hour are available on order.

| GBW | ||||||||||

| Modell | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| Transport capacity (m³/h) |

13,5 | 21 | 33 | 53 | 77 | 120 | 191 | 268 | 428 | 555 |

Optimised drive

The propulsion is provided by a retractable drive. The direct drive of the rubberised drive drum and the SKF bearing arrangement increases operational safety even more. For higher capacities, a separate motor-clutch-drive unit provides the drive.

Vertical transport

Material is loaded into the hopper. The material is transported to the driving head with circularly running buckets, then at the turn the material falls out of the buckets due to the centrifugal force and leaves the elevator through a slide.

Buckets depending on the material

The buckets are made in the dimensions according to DIN15234. In case of sticky materials, possibly in plastic, stainless steel or rubber lined design. Surfaces subject to abrasion may include an abrasion plate.

Chain elevators

We also make chain elevators for transporting high temperature materials (KBW). For materials above 120 degrees Celsius, the rubber belt will quickly age and the chain elevator offers safe operation and a reliable solution for such applications.

It is our expert colleagues’ pleasure to assist you.