Bag opener

Even with feed hopper

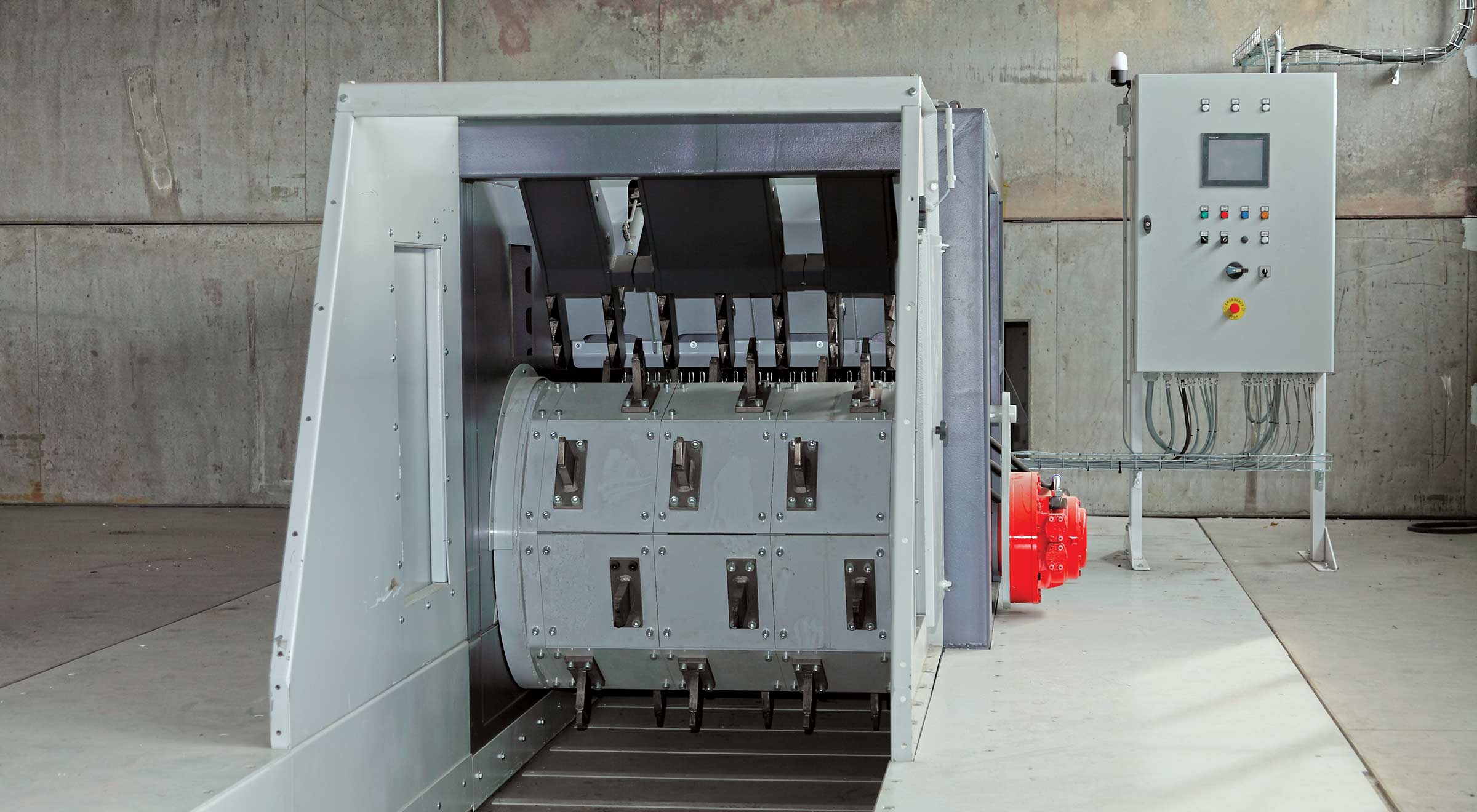

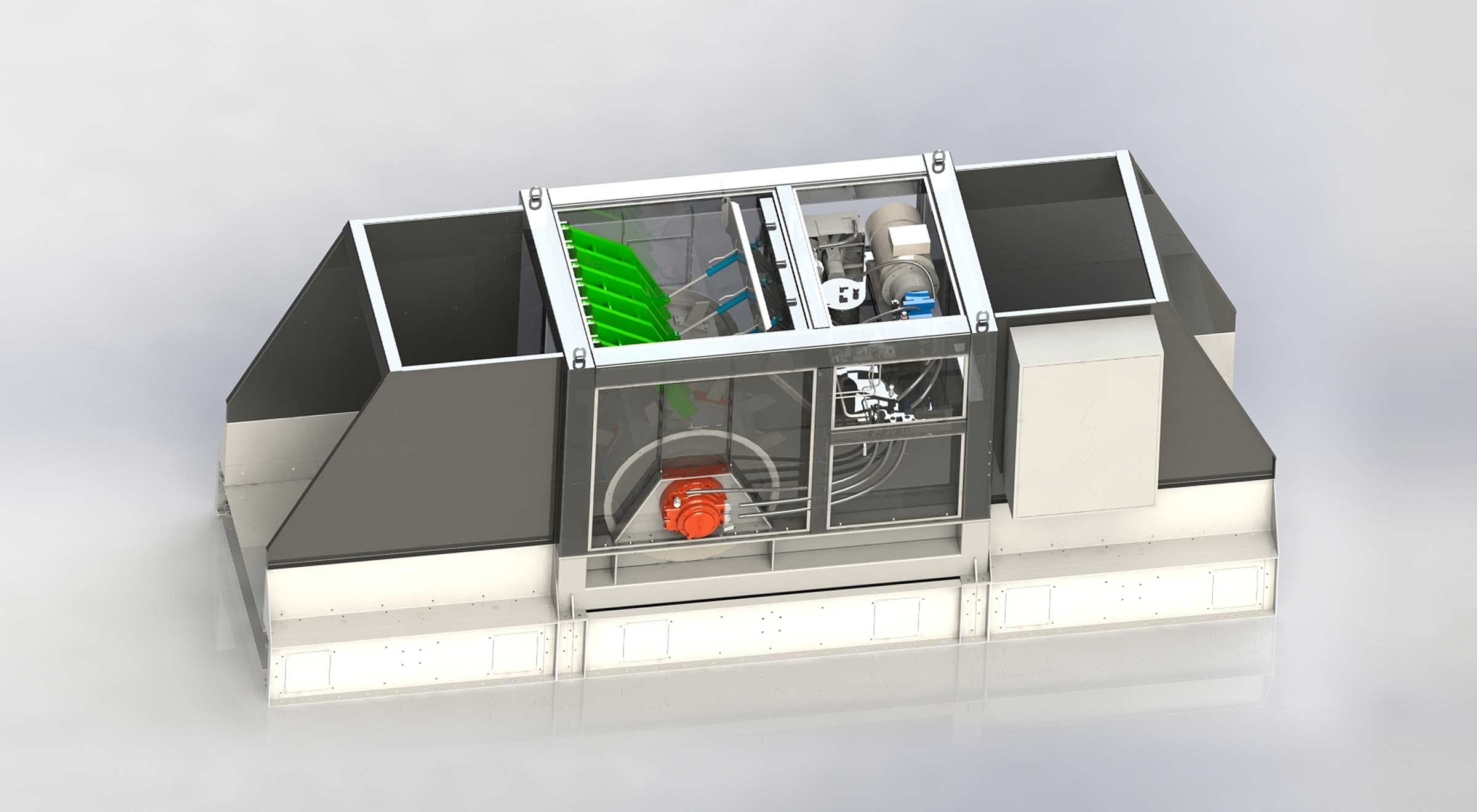

The equipment can be ordered with a container, as well. Its working width is 1500/1800 mm. The built-in, integrated conveyor belt carries the material to the rotating drum. In this case, the movement of the two machines is synchronized for the optimal operation. Processing capacity from the selective waste: max. 200 m³/h.

Simple design

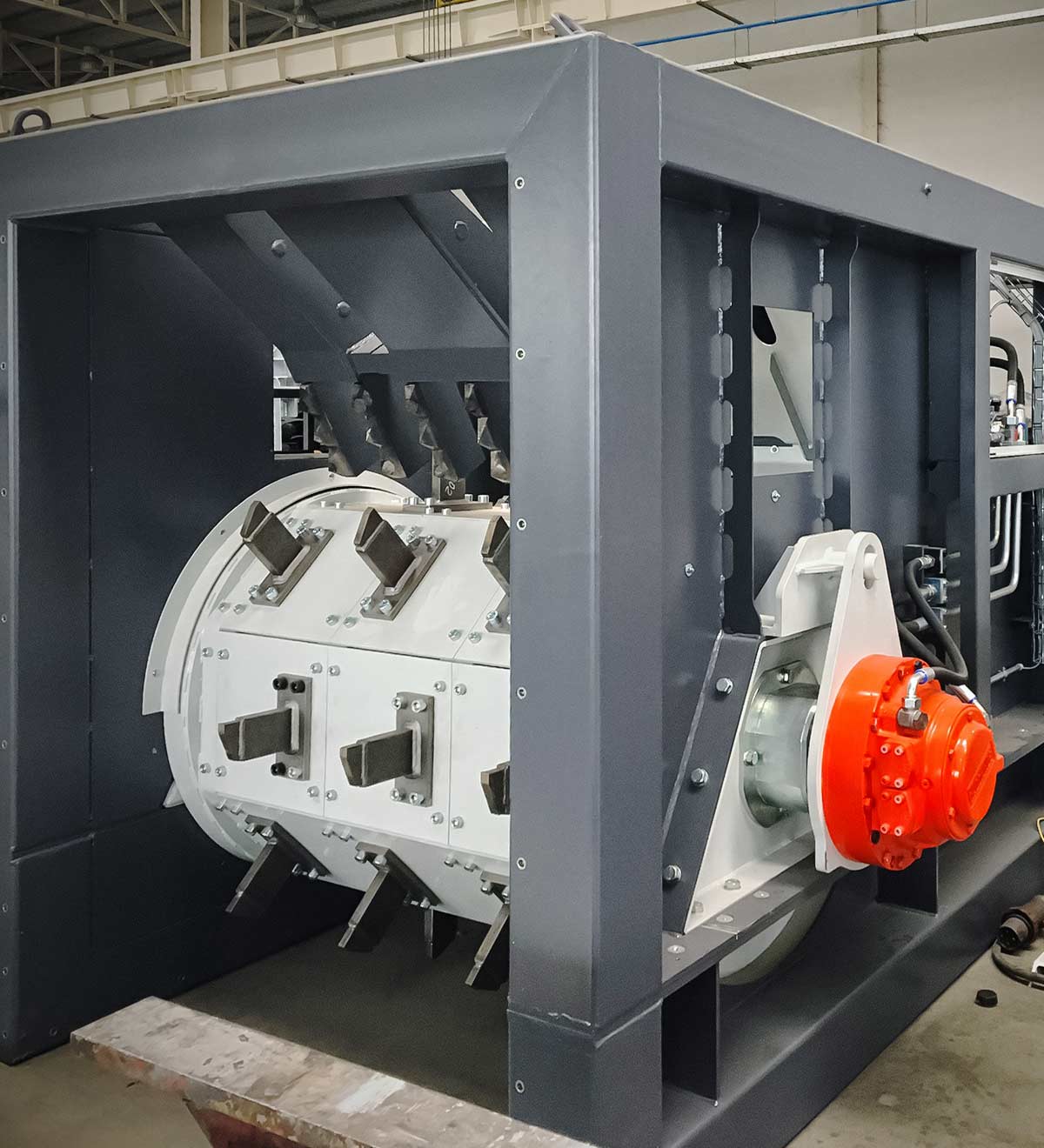

There is a stationary blade wall in the bag ripper, above the splitting drum. The pressure of the blade wall is controlled by a hydraulic cylinder; in case of heavy load, the pressure lever releases. The cylinder and the fixed blade wall together can ensure reliable tearing of the bags, emptying and loosening of their contents. The splitting blades on the drum are made of wear-resistant steel.

Efficient processing

The construction allows for reliable bag feeding and emptying without much damage to the contents of the bags. Thanks to the efficient operation of the machine, even the bag-in-bag fractions are well loosened, thereby it increases the recyclable material yield of the sorting system significantly. It can be used for several types of materials: packaging materials, household waste, paper waste.

Optimised drive

Its drive can be hydraulic (Hägglund -Bosch-Rexroth) or electric (SEW drive). The drive system reacts very quickly to shock loads, thus protecting the structure of the equipment by limiting the torque. Due to the limited torque, the load on the machine's teeth, bearings, and shafts is reduced. This also contributes to the reduction of the maintenance requirement of the equipment.