Sand washers

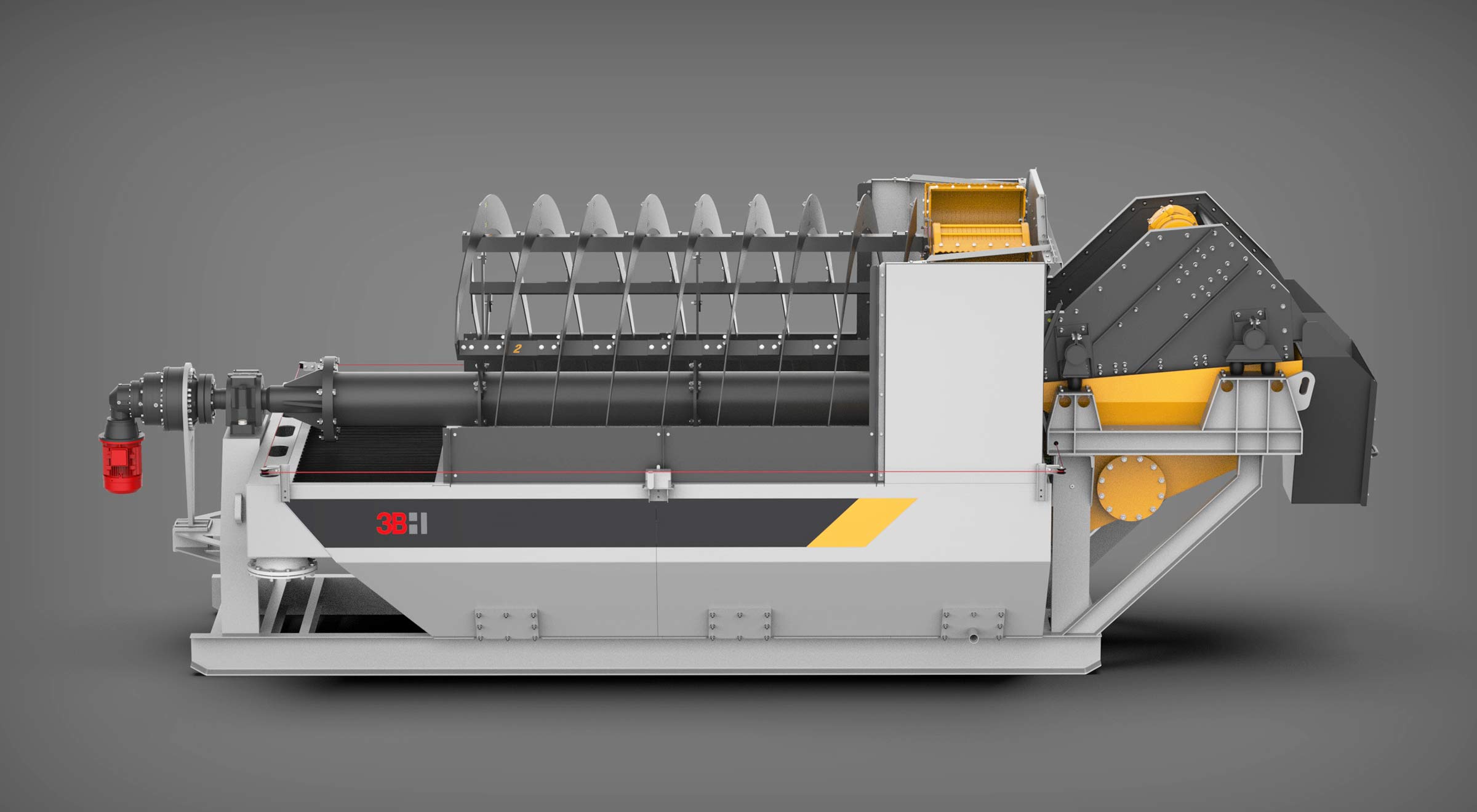

Sand washers produced by 3B are made mainly for gravel mines.

Proven design

During wet screening the sandy muddled water is drained to the trough. After the intake the bucket wheel lifts part of the watery sand immediately. The other part – the finer fractions – settle continuously in the trough, then the spiral fixed to the shaft continuously pushes the settled sand towards the bucket wheel and then it is lifted with the buckets on the desiccating sieve.

Designed for optimal production

The frequency regulator built in the control ensures the equal loading of the sand washers as well as the optimal desiccation of the sand.

For low capacity

The outer sand washers (SVa) lift the sand out with one or two bucket wheels then they feed it onto another conveyor. The lifting out is done with a very slow spin so that the sand lifted out is adequately desiccated.

In combination with a dewatering sieve

The inner sand washers (SViE) are made with one bucket wheel and right after the wheel there is a desiccation screen fixed on the sand washer, which performs the desiccation of the sand. This way a much higher capacity can be achieved even 100-150 t/h. The moisture content of the washed sand is max: 12-13 %.

Fine sand washers

Another field of use is the regaining of the fine sand (0.063-1 mm) from the muddled water. These sand washers operate at a very low RPM and are made with a larger trough.

It is our expert colleagues’ pleasure to assist you.