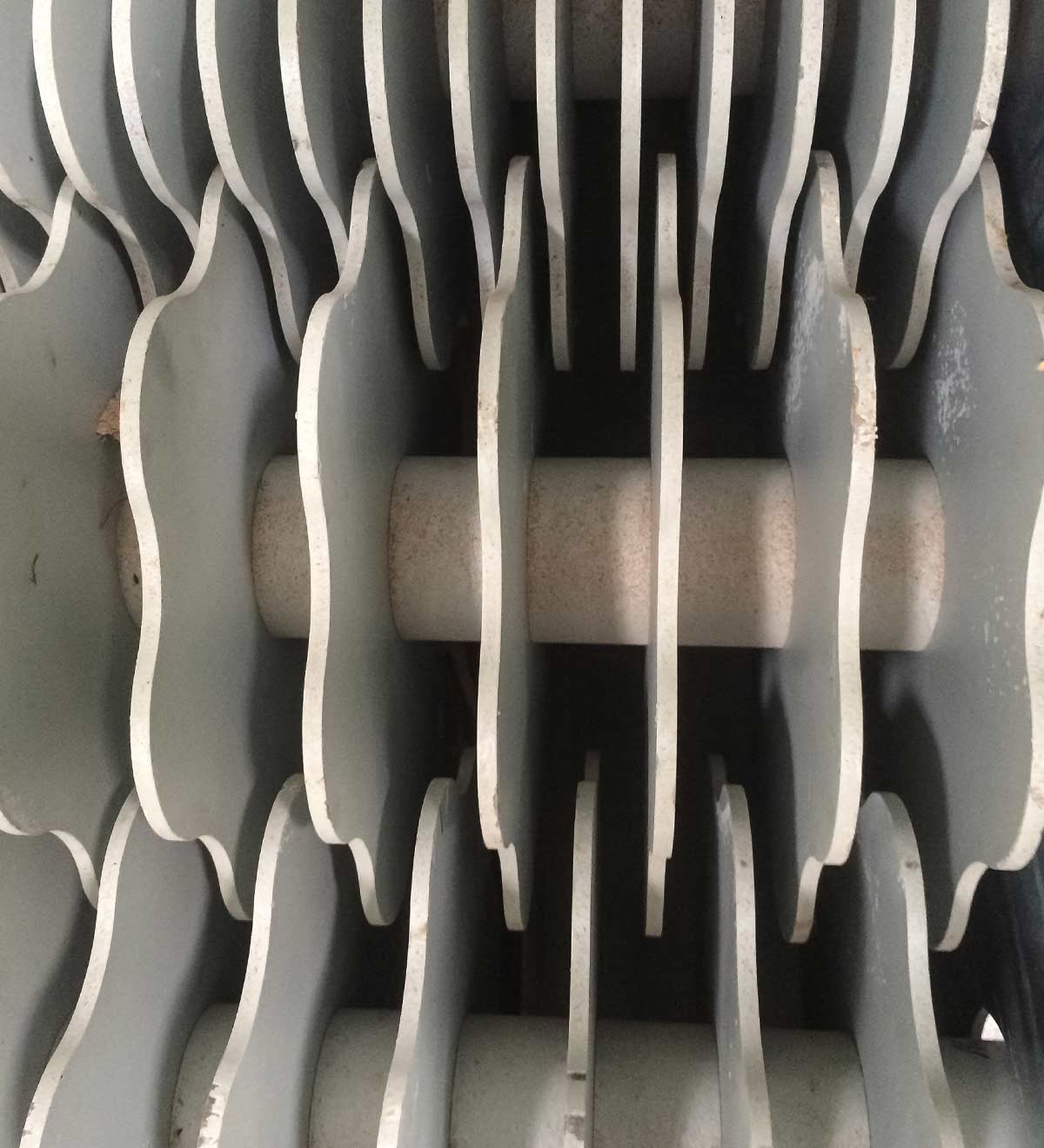

Disc screens

Disc screens provide a high-performance and excellent classification option for biomass and waste processing. The efficient processing of wood waste supports the renewable energy utilization guidelines by using discarded wood, and plant and vegetable waste as an energy source.

Designed for continuous operation

Thanks to the modular design, the length and capacity of the sieve can be adjusted to the given capacity. Massive equipment, which typically operates all year round without major servicing.

Simple operation

Each rotating shaft has profiled discs that are mounted at regular intervals. The incoming material is fed to one end of the screen. The rotating movement of the shafts moves the bulk material forward horizontally. Pieces of materials smaller than the distance between the discs fall through the screen, while pieces larger than the openings pass through it.

Grading and loosening

These screens are especially useful for grading and categorize biomass and waste, because they loosen the mass of material during the operation. The circumference (rim) of the discs is profiled for better mixing. They are dimensioned to handle stones and heavier dirt without damage, and to withstand the wear and tear resulting from grading.

Smart control

Stones, metals or large pieces of wood can get stuck on the disc screen and occasionally between the shafts. To avoid this, we developed an anti-jamming sequence, integrated into the control.

Dust-free environment

Processing biomass and waste can generate significant amount of dust. When planning a complete plant, the screen, the conveyor belts and the chutes are all supplied and delivered in a closed design, and dust filters are used to avoid the formation of particulate matter.

It is our expert colleagues’ pleasure to assist you.